Thermal control is the process of controlling the heat produced by electronic devices so as to avoid overheating and malfunctioning. It is a crucial component of electrical design and engineering, particularly in the age of rising power density and decreasing form factors that we live in today. The fundamentals of thermal management, including heat dissipation, typical sources of heat in electronic devices, and the various kinds of cooling systems like heat sink aluminum and materials available, are covered in this article as a beginner’s guide.

Common Sources of Heat in Electronic Devices

In addition to other sources like motors, transformers, and power supply, electronic gadgets also produce heat as a result of the electric current that flows through their circuits. High-performance processors and graphics cards are known for producing a lot of heat, necessitating the use of more effective cooling techniques. Battery-powered gadgets, high-power transistors, and LED illumination are some more typical heat sources in electronic equipment.

Heat Dissipation: Why is it important?

The process by which heat is transported from electronic equipment to the environment is known as heat dissipation. In order to keep device performance and reliability at their highest levels, effective heat dissipation is necessary. Electronic equipment might overheat if the heat it produces is not effectively dispersed, which could result in component failure, performance degradation, or even fire dangers.

Types of Cooling Systems and Materials

To control the heat in electrical equipment, a variety of cooling techniques and materials are available. The specific gadget, its power density, form factor, and cooling requirements determine the cooling system and material to use. Below are a few of the materials and cooling equipment that are frequently utilized:

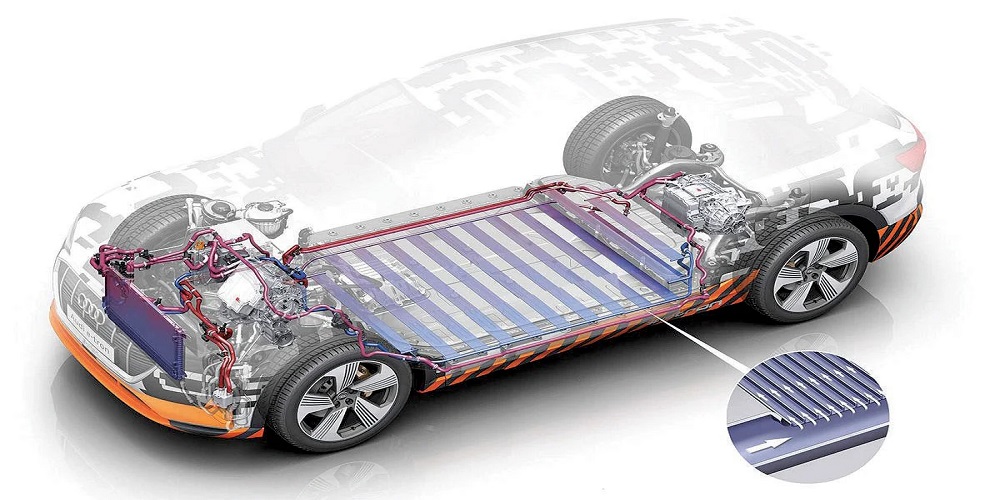

Liquid Cooling

In liquid cooling, heat is removed from the device by using a coolant fluid, such as water or a solution of water and glycol. The heat-producing parts of the device are in touch with a number of tubes or channels through which the coolant is pumped. Although liquid cooling is more effective than air cooling, its implementation is more difficult and expensive.

Phase Change Cooling

Refrigerants are used in phase change cooling to remove heat from the apparatus. In a continuous cycle, the refrigerant evaporates and condenses, absorbing heat from the apparatus in the process. The intricacy of phase change cooling necessitates careful design and implementation despite its great efficiency.

Air Cooling

The most popular cooling technique in electronic equipment is air cooling. Fans and heat sinks are used to disperse heat from the gadget to the surrounding air. Aluminum, copper, and graphite, which have strong thermal conductivities and effectively transmit heat, are used to make heat sinks.

Thermoelectric Cooling

Using a thermoelectric module, which produces a temperature gradient when an electric current is applied, allows for thermoelectric cooling. As the module comes into touch with the device’s heat-producing parts, heat is transported away from the device as a result of the temperature gradient. The size and power requirements of the module somewhat constrain the efficiency of thermoelectric cooling.

Conclusion

Thermal management is a crucial component of electronic design and engineering to ensure maximum device performance and durability. Several cooling techniques and materials are available to manage heat in electronic equipment, which is important to keep electronics from overheating and malfunctioning. The specific gadget’s power density, form factor, and cooling requirements determine the cooling system and material to use. Engineers may build and create more dependable and effective electronic equipment that fulfills the needs of today’s technology-driven world by having a basic understanding of heat management.