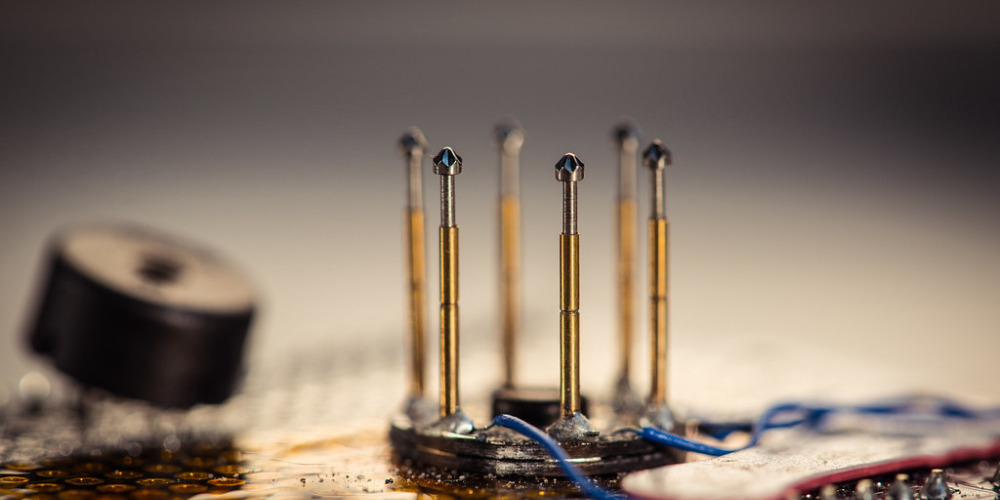

Different types of pogo pin by design

There are several types of pogo pins available, each with a different design suited for specific applications. Here are some of the most common types of pogo pins:

- Barrel-type Pogo Pins: These pogo pins are cylindrical in shape and feature a spring-loaded contact at one end, which makes contact with a mating pad or contact on a PCB.

- Crown-type Pogo Pins: The pogo pin features a flat, circular contact at the end of a spring-loaded plunger, which can make contact with a flat pad or contact on a PCB.

- Cup-type Pogo Pins: These pogo pins feature a cup-shaped contact at the end of a spring-loaded plunger, which can make contact with a spherical or rounded pad on a PCB.

- Blade-type Pogo Pins: These pogo pins feature a thin, flat contact blade at the end of a spring-loaded plunger, which can make contact with a slot or groove on a PCB.

- Wire-wrap Pogo Pins: These pogo pins are designed for use in wire-wrap applications and feature a long, thin plunger that can be wrapped around a wire to make contact with a PCB.

Each type of pogo pin has its own set of advantages and disadvantages, and selecting the right type for a particular application will depend on factors such as the required current rating, contact force, and mating cycle requirements

Merits of pogo pin

Pogo pins offer several advantages that make them a popular choice for many applications. Here are some of the primary advantages of pogo pins:

- High Reliability: Pogo pins provide a reliable and secure connection, even in high-vibration or high-shock environments. This makes them an excellent choice for applications that require a stable connection.

- Repeatability: Pogo pins provide consistent and repeatable connections, even after repeated use. This makes them ideal for applications that require frequent connections and disconnections.

- Space Saving: Pogo pins require less space than other types of connectors, such as traditional wire connectors or soldered connections. This can be a significant advantage in applications with limited space.

Demerits of pogo pin

While pogo pins have several advantages, there are also some potential disadvantages to consider when using them in a particular application:

- Limited Current-Carrying Capacity: Pogo pins may have limited current-carrying capacity, depending on the size and design of the pin. This can limit their use in applications that require high-current carrying capability.

- Wear and Tear: With repeated use, the spring in a pogo pin may weaken over time, reducing its reliability and lifespan.

- Environmental Limitations: Pogo pins may not be suitable for use in harsh environments, such as those with extreme temperatures or corrosive substances. Exposure to moisture or other contaminants can also affect their performance.

- Cost: Pogo pins can be more expensive than other types of connectors, which can be a consideration for cost-sensitive applications.

- Mating Pad Design: The design of the mating pad or contact on the PCB can affect the performance of the pogo pin, and not all PCB designs may be compatible with pogo pins.

It’s essential to consider these potential disadvantages when selecting and using pogo pins in a particular application