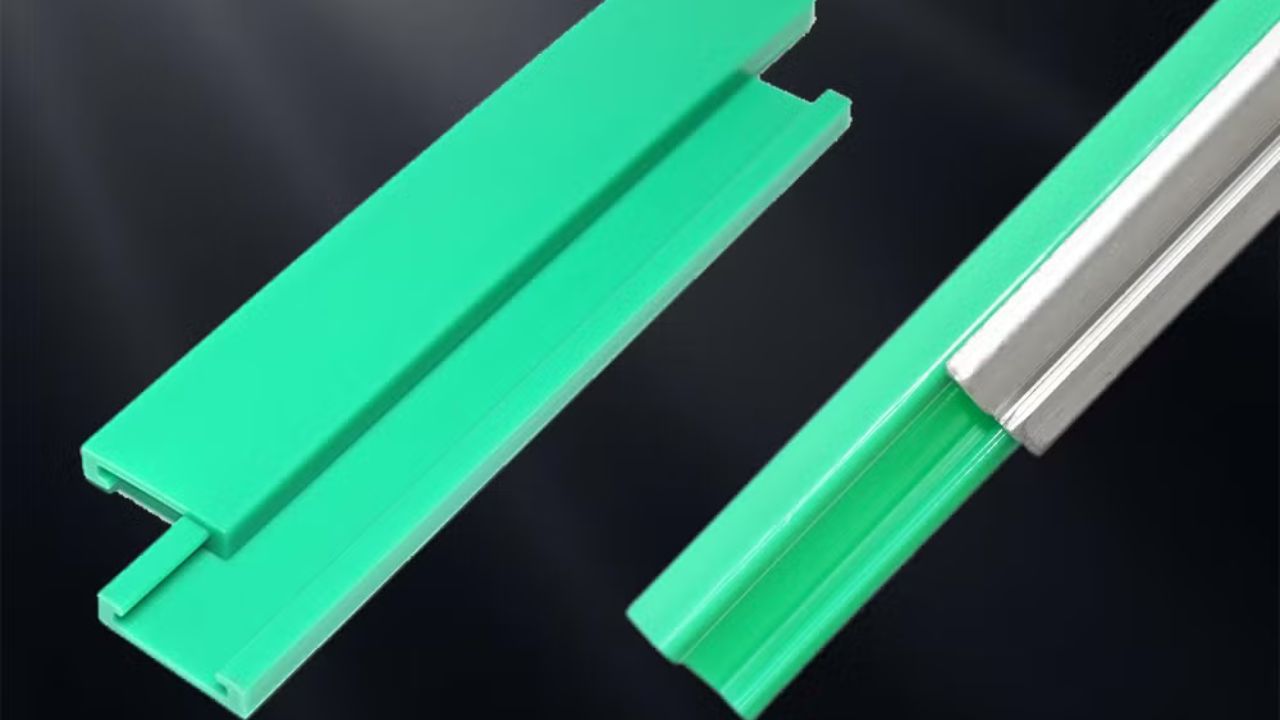

The UHMWPE wear strips (Ultra High Molecular Weight Polyethylene) have become one of the critical elements of the contemporary manufacturing sector. These strips are distinguished by a high level of durability and low-friction characteristics and are applied in numerous projects, such as conveyor systems, heavy equipment. The manufacturing processes that involve high movement rates, abrasion, or chemical exposure usually face problems of equipment wear, higher maintenance costs, and inefficiencies. The uhmwpe wear strips are a solution to this problem as they lower the friction, lower wear, and increase the life of industrial equipment, which ensures the flow of operations and improved productivity.

Exceptional Wear Resistance

Apart from the high wear resistance, which is one of the greatest benefits of UHMWPE wear strips in the manufacturing process. UHMWPE is a material that does not degrade under heavy mechanical impact and sustained abrasion as compared to traditional materials. This feature is what renders it especially applicable to high-wear wear like chutes, hoppers, and conveyor guides. The wear strips of UHMWPE minimize the frequency of replacement of the important parts of machinery due to wear, which saves time and operational expenses. These strips are essential to industries dealing with bulk materials or abrasive substances so as to keep the equipment operational in the long term.

Low Friction for Improved Efficiency

The other important advantage of UHMWPE wear strips is that they have a low coefficient of friction. In manufacturing plants, where machines and materials are always in motion, too much friction may result in higher energy usage and faster deterioration of machines. UHMWPE wear strips enable free movement of the mechanical components and materials, which leads to less resistance and efficiency. This characteristic of low friction not only enhances the speed and reliability of the production lines but also helps save energy. UHMWPE strips ensure that manufacturers have an improved throughput with a longer equipment life by allowing a smoother movement.

Resistance to Chemicals and Moisture

Exposure to rough chemicals and wet conditions that are commonplace in manufacturing processes may compromise the performance of regular materials. The UHMWPE wear strips have excellent resistance properties to a large variety of chemicals, such as acids, alkalis, and solvents. This chemical resistance could be employed to ensure that the strips are structurally intact even in adverse conditions. Moreover, UHMWPE is not an absorbent material, and therefore, it does not swell or deform when there is moisture. All these characteristics make UHMWPE wear strips suitable for use in the industry, such as food production, chemical production, and water treatment, where the equipment used is frequently subjected to corrosive material and wet environments.

Easy Installation and Customization

UHMWPE wear strips have been engineered to fit many manufacturing applications. They come in various sizes and thicknesses and can be freely cut or molded to meet the needs of certain machinery. This flexibility enables manufacturers to make customized installations without having to make a lot of changes to the available equipment. The downtime is also minimized by the ease of installation, allowing the companies to continue with production. UHMWPE wear strips allow practicality and efficiency in the industrial environment by offering an all-purpose and easy-to-use solution.

Cost-Effectiveness and Long-Term Benefits

Though UHMWPE wear strips might be more costly to install at the start than other conventional wear strips, it is a long-term worthwhile investment that can pay off. These strips prevent the occurrence of repair and replacement as they limit the wear and tear on the machinery. This creates a reduction in the maintenance costs and time spent in production, which in the end increases profitability. Besides, the effectiveness and resourcefulness of UHMWPE wear strips also make them an effective solution that prolongs the life of the equipment, which makes them rather affordable among manufacturers who aim at sustainable solutions.

Conclusion

The wear strips of UHMWPE have proven to be a necessary material in the current manufacturing industries because of the blend of wear resistance, low friction and chemical resistance, moisture resistance, easy set up and long-term economical advantages. These strips work to enhance the efficiency of operations and increase the life of industrial equipment by minimizing friction and preventing abrasion of equipment. UHMWPE wear strips are still used by manufacturers in different industries in a bid to improve their productivity, minimize maintenance expenses, and even ensure smooth and continuous operations. With more changes in manufacturing demands, it was found that UHMWPE wear strips could continue to provide an effective and dependable solution to the high wear and high-performance industries.