It is the ideal choice for applications that require high strength, and lightweight materials since it has a low density but outstanding durability. Custom-machined parts made of aluminum have great corrosion and chemical resistance; they are non-magnetic, inert, and good conductors of electric power and heat.

Custom aluminum parts are cost-effective and durable, whether you require an initial run or a large volume of them. Excellent flexibility and elasticity are characteristics of aluminum which means it can be easily shaped by rolling or striking and may be pushed into different shapes without breaking.

Due to its strong mechanical qualities, including longevity, the ability to be, and a high strength-to-weight ratio, aluminum is one of the most often used materials for industrial parts.

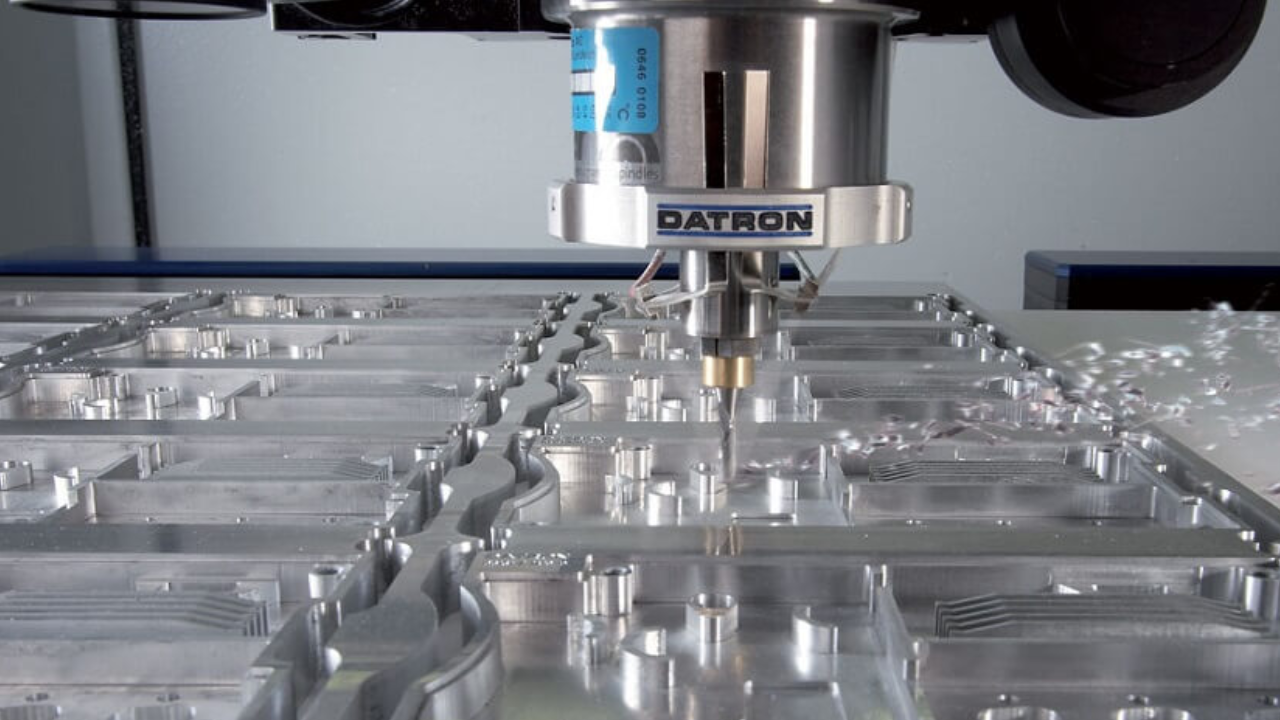

Custom aluminum parts can be produced with a high level of precision and complex geometries using CNC machining.

What are Customized Aluminum Components, and Why Are They Used?

Custom aluminum parts are constructed from aluminum and are created to meet certain specifications and functionalities. In many sectors, including aerospace, automotive, electronics, and consumer goods, where accuracy, power, and longevity are crucial, custom aluminum parts are used.

How long does it typically take to complete a Project to Manufacture Custom Aluminum Parts?

According to the project’s difficulty and size, the turnaround time when producing custom aluminum parts varies. From the time an order is placed, we can typically finish the majority of tasks in 2-4 weeks. However, after reviewing your exact needs and project scope, we can offer you a precise lead time.

Why Make Custom Parts Out of Aluminum?

Aluminum is a lightweight and somewhat soft metal. Likewise, this metal is relatively simple to process and has excellent corrosion resistance. In actuality, aluminum is the sixth most ductile metal and the second most malleable substance. In addition, aluminum functions well as the alloy of choice for building automobiles and other forms of transportation.

Aluminum is the ideal material for bespoke parts due to several factors. The obvious material of choice for electrical cables is aluminum because it is a good heat and electrical conductor. Additionally, it has a higher strength-to-weight ratio than copper and is less expensive.

Industries that Gain from Custom Aluminum Parts Manufacturing

Automotive

Aluminum has many uses in the automotive sector since it is durable, thin, and easy to process. To reduce fuel use and pollution, aluminum components help engines run more efficiently. Additionally, they improve safety by absorbing a significant amount of the shock produced by auto crashes, reducing injuries to people.

Aerospace

Aluminum components that have been specifically machined can withstand the intense pressures and stresses that airplanes encounter at great altitudes without losing structural integrity. Architects can significantly lower the weight of an airplane by using aluminum parts instead of steel, which would improve fuel efficiency and increase the number of customers or the amount of cargo the plane can handle.

Food processing and packaging

Aluminum components, particularly those that have been oxidized (a process that creates a layer of aluminum oxide on the surface), are frequently used in assembly lines for food packing. Aluminum that has been lacquered has significantly greater corrosion and scratch resistance, as well as being stronger. Due to this, it is perfect for components with high levels of friction, including belt pulleys.

Telecommunications

Covers, spaces, and heat sink housings are just a few examples of the crucial components for telecommunications that are made of aluminum. High levels of precision are necessary for telecom cavities, and aluminum CNC machining makes this task simple. Aluminum components that were specifically machined help safeguard delicate machinery and are essential for communication and delivery.

Conclusion

Metals made of aluminum alloys are very adaptable and are employed in numerous global sectors. Precision engineering, material science, and creativity come together in perfect harmony in custom aluminum parts. Aluminum’s heat conductivity and electromagnetic shielding qualities are advantageous for electronics. Aluminum components even in common consumer goods improve the way they look and work.